| Sign In | Join Free | My ecer.com.ru |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ecer.com.ru |

|

Brand Name : Lingyao

Model Number : LYQCL100

Certification : CE, ISO, GMP

Place of Origin : China

MOQ : 1 unit

Price : USD 150,000-350,000 per unit

Payment Terms : D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : 1 unit per month

Delivery Time : 180 work days

Packaging Details : carton, wood carton, pallets

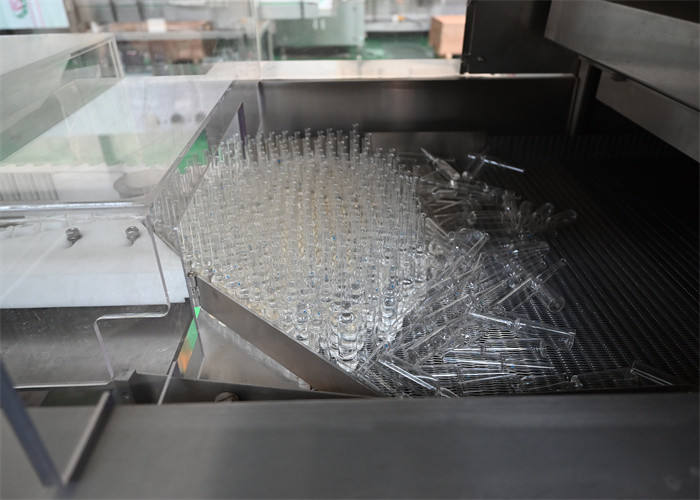

Machine Name : Ampoule filling and sealing machine

Function : Ampoules Washing, Sterilization, Filling, Sealing

Filling Liquid Type : Influenza Vaccine Injectables

Filling Volume : 1-10ml

Ampoules Material : Glass

Clarity : >99%

Output(1-2ml) : 16000-22000pcs/h

Filling Accuracy : +/-0.5%

Breakage Rate : <0.5%

Nitrogen Filling : Yes

Total power : around 72kw 380V 50HZ

CIP/SIP : Available

Oven Cooling Style : Air Cooling

LAF System : ISO Class 5

Ampoule Filling And Sealing Machine For Influenza Vaccine Injectables with Isolator, High-Efficiency Ampoule Filling Line

This machine is designed for the efficient filling and sealing of injectables in ampoules,

specifically for volumes ranging from 1 to 20 ml. It features:

Machine Spec:

| technical parameters | ||||

| product model | LYQCL100+LYASMR 620/43+LYAGF8 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 16000-22000pcs/h | |||

| Output(5-10ml) | 8000-12000pcs/h | |||

| Output(20ml) | 5000-7000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 72kw 380V 50HZ | |||

| Outline size | around 9940x2260x2445mm | |||

Whether you're producing small batches or scaling up for large-scale manufacturing, our ampoule filling line delivers

unmatched accuracy and reliability. With its modular design and customizable options, it adapts to your unique production

needs, ensuring optimal performance every time.

Step ahead of the competition with a solution that combines innovation, efficiency, and regulatory compliance. Discover

how our ampoule filling line can revolutionize your production process and elevate your business to new heights.

Key Features:

○ GMP-compliant design

○ 304 stainless steel work surface

○ Hygienic materials for fluid-contact parts

○ Advanced PLC and touchscreen controls

○ Real-time monitoring and fault diagnosis

○ Scalable and customizable solutions

upgrade your production with the best-in-class ampoule filling line. Contact us today to learn more!

|

|

Ampoule Filling And Sealing Machine For Influenza Vaccine Injectables with Isolator, High-Efficiency Ampoule Filling Line Images |